V-tech Dynamometers - Chassis Dynamometers Manufacturer

Features:

- Amazing accuracy – up to 3000 true measurement points per second, measurement error below 0.1%

- Extremely popular - hundreds of installations Worldwide - see in Gallery

- XXI Century Dyno - special TractionBoost knurling for rollers working perfectly for high torque electric and hybrid cars. No slipping.

- Modularity - buy an inertial dyno, add an eddy current brake, or AWD (4x4) extension later.

- Full 1:1 mechanical synchronisation of axles in 4x4 dynos

- TÜV certified. Installation is entirely compliant with the applicable regulations.

- Chosen by rally and racing teams - see hundreds of photos.

- Produced by tuners for tuners – resulting in complete ease of handling.

- Dynos have the full support of our service. You can extend the warranty time to a lifetime warranty.

- Multiple configurations and options of dynamometers are available.

- A software upgrade is free if we service the dyno.

Last Expo/Fairs

Our stand at Professional Motorsport World Expo in Cologne with a new chassis dynamometer, designed for the era of electric cars was shown.

AWD and 2WD dynamometers have enormous traction thanks to a new, bi-prismatic knurling design.

Electric cars have high torque, available from low rpm, demanding dynamometer traction capabilities to be enhanced.

We did it.

How to Choose a Good Dyno

Which dyno to buy? How to choose the right one.

News / Blog

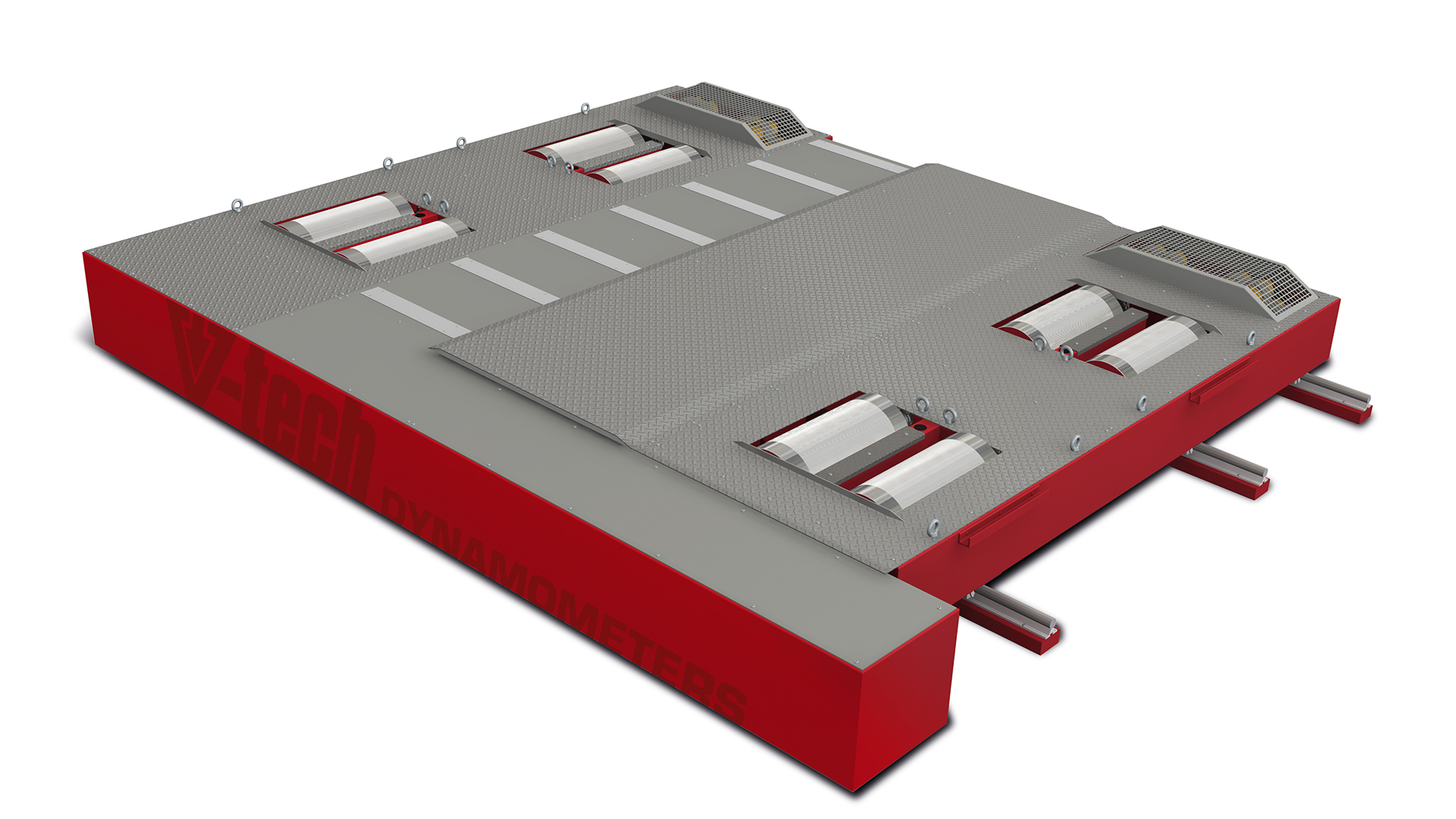

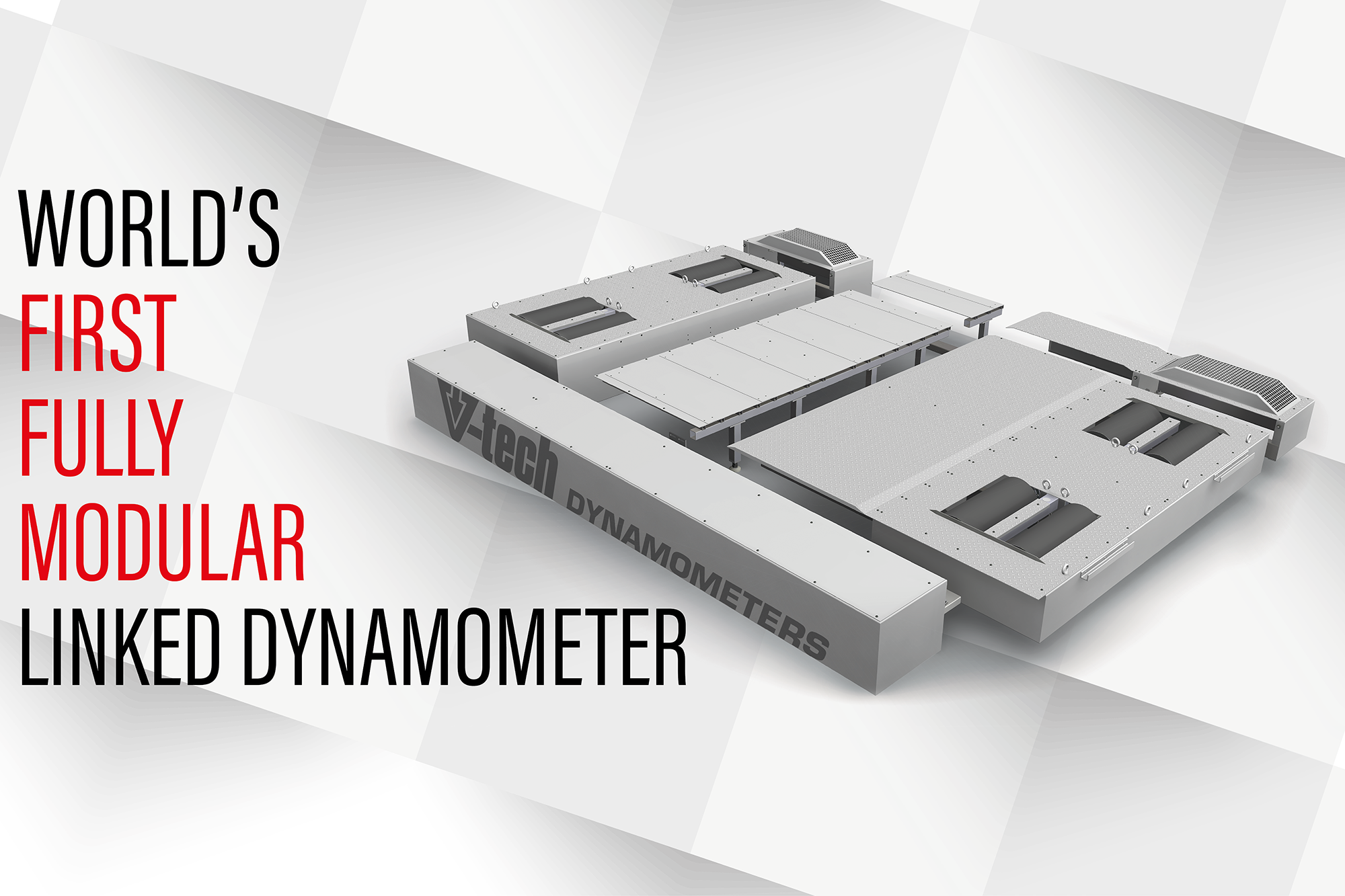

A modular dynamometer means no need to buy an AWD (4x4) dyno at once. Be smart, think clever! Rise your sales and let your dynamometer pay off itself!

Starting with a front, single axle module without electromagnetic brakes, you can add AWD extension, brakes, and extra sensors later. Thanks to the fully modular design, everything is expandable.

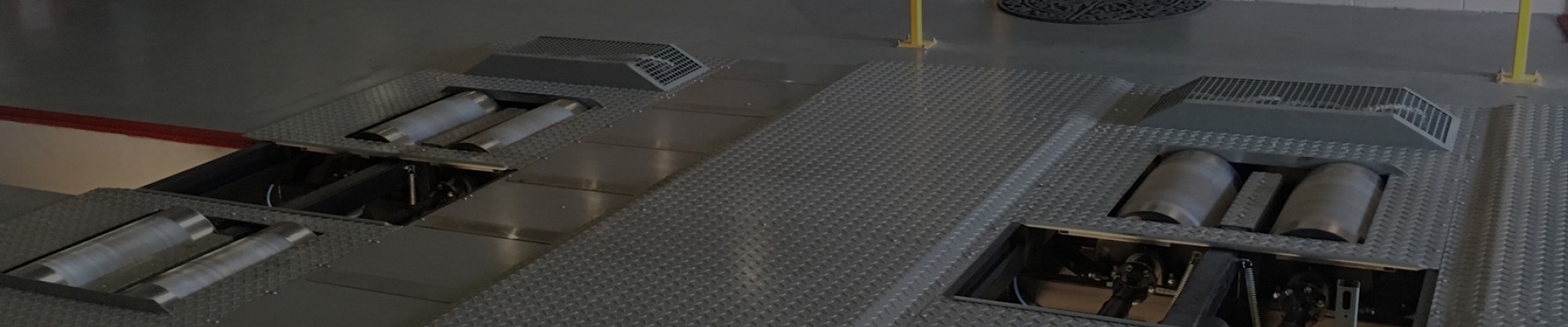

Our first rolling road was created and installed in 1999, and from the very beginning, it featured an exceptional accuracy of measurement and reliability. Today's variants of our dynamometers include modular one axle dynamometer and AWD chassis dynamometer (4x4 vehicles). As standard, all have unique, new TractionBoost knurling. It enables safe and precise measuring of high-performance cars like Tesla, Porsche…and supercars. Multiple models, configurations and options of the chassis dynamometer product line are available.

Our dynamometers are available in both inertial and braked versions. Additionally, in the 4x4 version, we use a novelty system of mechanical synchronisation of front and rear axles, which allows measuring the most modern cars equipped with active traction control systems. Also, dynamometers for motorcycles and quads, RVs, Agri and trucks are available.

We manufacture certified dynos built according to the applicable European standards.

Read more in press release: V-tech dynamometers.

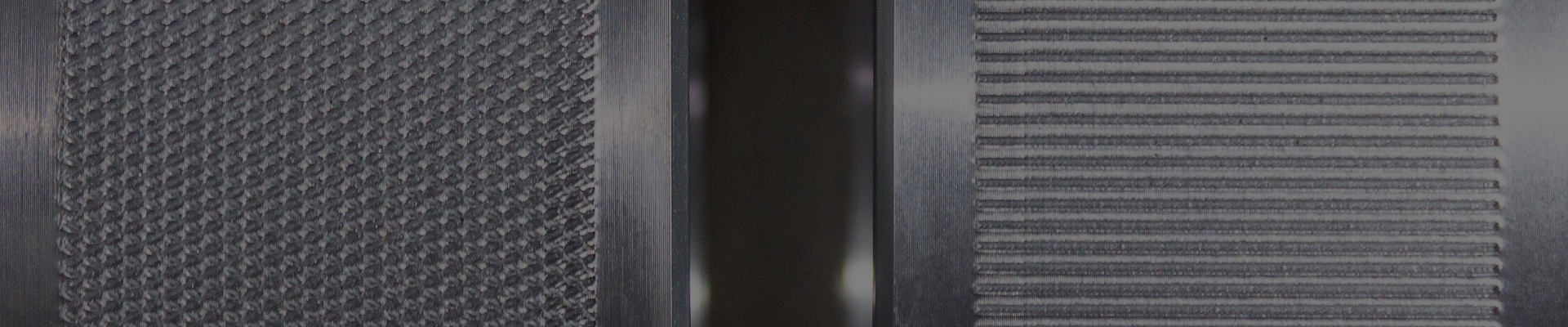

Many popular chassis dynamometers manufacturers use lightweight painted rolls and cover them with adhesive glue & sand or glass-bedding. Such rollers wear out quickly and will never (neither new nor worn out) provide good friction and generally look unsightly.

We emboss unique tread (using high mechanical pressure) with a much-improved knurling design called TractionBoost. It uses bi-prismatic tread to prepare dyno for the era of electric cars.

The tyre cannot move in either direction when it contacts the roller, so there is less heat and noise.

Finally, the rollers are coated with a unique two-layer chrome coating to protect them from wear. Your dyno will always catch the eye of your customers. Even ten years of use will not reduce their performance or ruin their aesthetics.

In addition, rollers with a larger diameter and heavier weight better replicate the road conditions for which the tyres were designed and are generally safer.